Notes from Faculty:

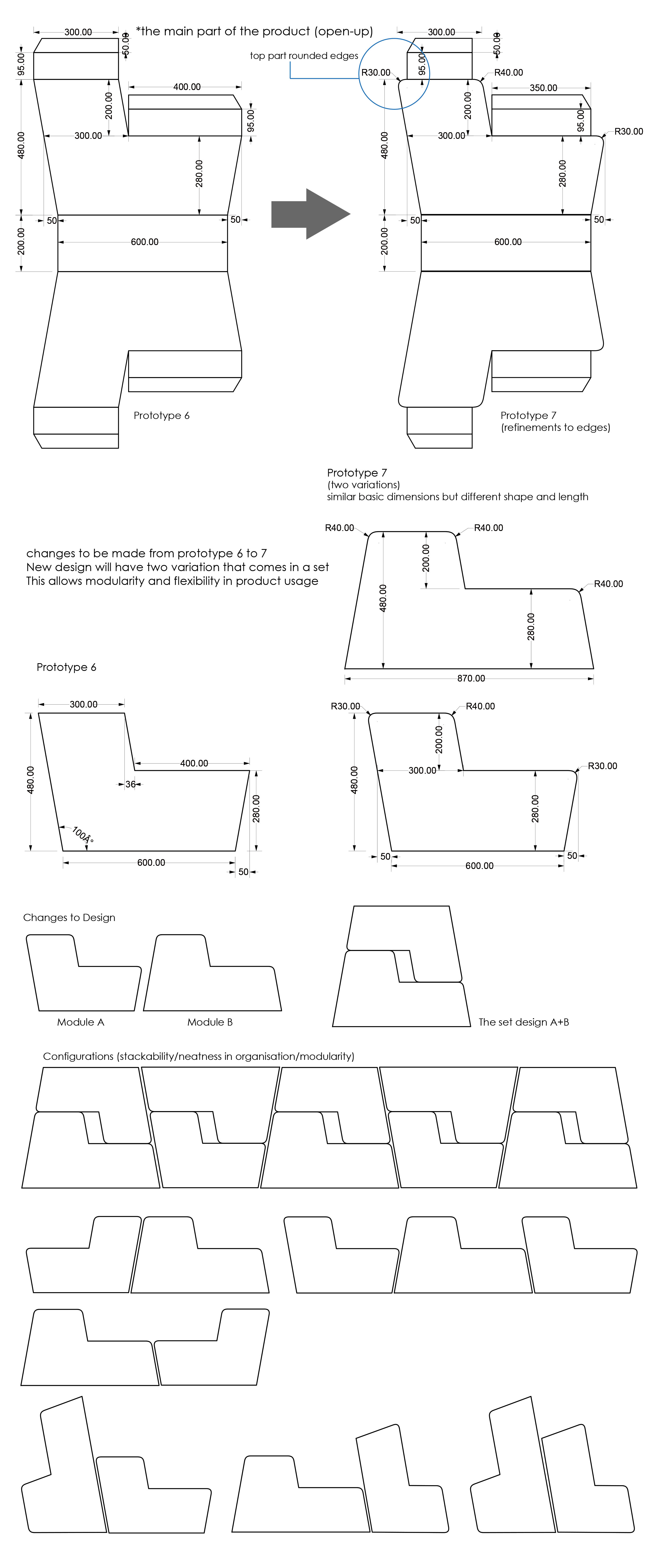

– The modules look abit static

(suggest/intro a 2nd generation of Cardblocks with kinetic features)

– Kinetic features like rocker/rollers on base .etc

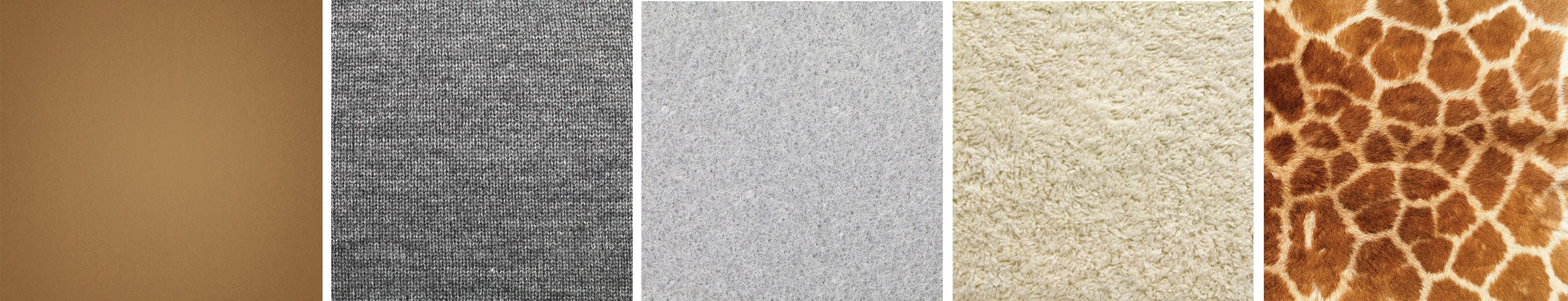

– Have more options for colours and fabric textures

(this was thought of earlier but not implemented much, to limit consumer’s choices)

– Packaging lacks placement security (parts may fall off)

Personal notes:

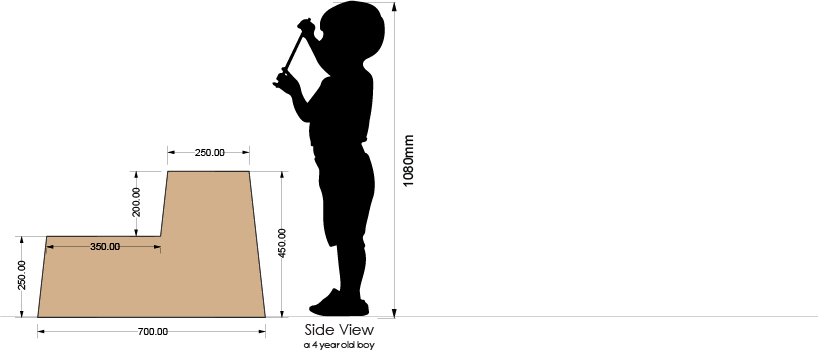

– Develop an optional curved base that is removable (rocker chair)

this will have several safety issues and the product might not be as equally strong as before

– Develop a bigger packaging with an integrated carrying handle

i have tried to use cardboard/craft paper to make the bag that wraps the parts but the folds support & handle part is too fragile and tears easily

– I will decide to do a catalog for more colours and fabric types, QR-coded on packaging

This will be on the webpage that will be created specially for Cardblocks

WEBPAGE will have

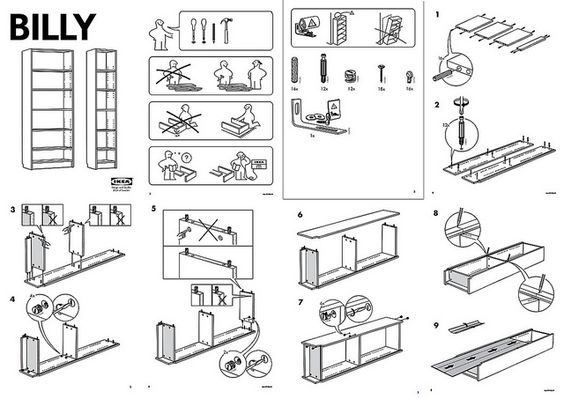

– Cardblocks Promotional Video

– uploaded videos of steps and instructions

– full catalog of additional materials (though samples will only focus on one type of material)

– tips on customizing product

– all other important info and features of Cardblocks

![finalda [Converted]](../../wp-content/uploads/sites/138/2016/02/finalda-Converted.jpg)

![s [Converted]](../../wp-content/uploads/sites/138/2016/02/s-Converted.jpg)